Printing has come a long way since the days of the Gutenberg printing press. From the emergence of offset printing in the 20th century to the digital printing technology that we see today, the world of printing has seen a significant shift over the years.

In this day and age, where everything is going digital, it’s important to understand how it has revolutionized printing and what the future holds. Whether you’re a design professional, a tech enthusiast, or just someone curious about the world of printing, let’s take a deep dive into the history and future of digital printing technology.

Overview of Digital Printing: What Is It and How Does It Work?

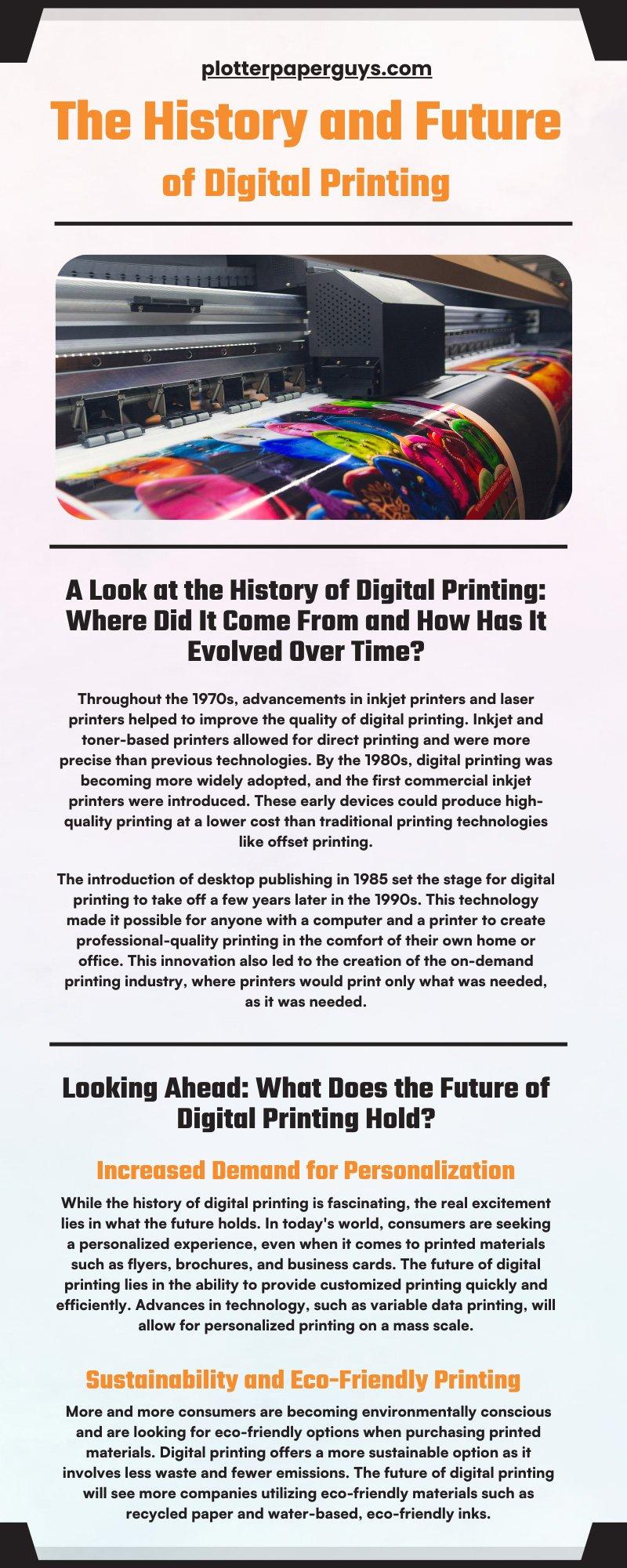

Before we get into the history of digital printing, it’s important to understand what digital printing is and how it works. Digital printing is a method of producing prints using digital files that are transferred directly onto a substrate or medium, such as paper, vinyl, fabric, or plastic. The images are created on a computer screen, and then the printer reproduces the image onto the printing substrate. Unlike traditional printmaking techniques that require a separate plate for each color, digital printing can reproduce full-color images in a single pass.

Digital printing machines use four-color process (CMYK, which stands for cyan, magenta, yellow, and black) inks or toners to create the full-color spectrum. However, some digital printing machines also use additional colors, such as orange, green, or violet, to extend the gamut of colors that they can produce.

Most digital printers use two main technologies: inkjet or laser. Inkjet printers use liquid ink sprayed through tiny nozzles onto the printing substrate, while laser printers use toner particles that adhere to the substrate using electrostatic charges.

A Look at the History of Digital Printing: Where Did It Come From and How Has It Evolved Over Time?

The history of digital printing is somewhat difficult to trace because it doesn’t boast an overnight success story. We can trace modern printing back to the 1950s when offset lithography emerged. It wasn’t until the late 1960s that the first rotary-style digital printing press was created, which could print text onto continuous-tab output devices in large quantities.

Throughout the 1970s, advancements in inkjet printers and laser printers helped to improve the quality of digital printing. Inkjet and toner-based printers allowed for direct printing and were more precise than previous technologies. By the 1980s, digital printing was becoming more widely adopted, and the first commercial inkjet printers were introduced. These early devices could produce high-quality printing at a lower cost than traditional printing technologies like offset printing.

The introduction of desktop publishing in 1985 set the stage for digital printing to take off a few years later in the 1990s. This technology made it possible for anyone with a computer and a printer to create professional-quality printing in the comfort of their own home or office. This innovation also led to the creation of the on-demand printing industry, where printers would print only what was needed, as it was needed.

Three significant developments helped to make digital printing what we know today. First, advances in printhead technology allowed for higher resolution and faster printing. Second, the development of software tools for graphic design made digital printing more customizable and accessible. Third, the rise of the internet in the 1990s led to the creation of web-to-print services, which revolutionized digital printing.

Today, the digital printing industry has evolved into modern printing techniques like printing with solvent-based inks, UV-curable inks, aqueous inks, and other inkjet technologies. Industries now have the ability to personalize and customize output for each individual customer. Moreover, a broader range of materials can now be printed on, making it possible to create customized designs on metal, glass, and plastics.

Looking Ahead: What Does the Future of Digital Printing Hold?

Increased Demand for Personalization

While the history of digital printing is fascinating, the real excitement lies in what the future holds. In today’s world, consumers are seeking a personalized experience, even when it comes to printed materials such as flyers, brochures, and business cards. The future of digital printing lies in the ability to provide customized printing quickly and efficiently. Advances in technology, such as variable data printing, will allow for personalized printing on a mass scale.

Sustainability and Eco-Friendly Printing

More and more consumers are becoming environmentally conscious and are looking for eco-friendly options when purchasing printed materials. Digital printing offers a more sustainable option as it involves less waste and fewer emissions. The future of digital printing will see more companies utilizing eco-friendly materials such as recycled paper and water-based, eco-friendly inks.

Integration With IoT and Cloud

In the coming years, we can expect to see more integration between digital printing and various technologies such as the Internet of Things (IoT) and cloud computing. As more and more businesses move their printing operations to the cloud, the opportunities to print from anywhere without requiring IT infrastructure significantly expand.

Additionally, printers themselves may one day become smart enough to determine suitable paper or ink on the cloud and make adjustments accordingly. Such integration would not only make printing more convenient but also enhance the user experience manifold.

Expansion of Digital Textile Printing

Digital textile printing is a rapidly growing sector of the digital printing industry. This form of printing allows creators to use inkjet technology to print dyes directly onto fabric. Advances in technology have made it possible to produce high-quality printed textiles quickly and efficiently. The future of digital printing will see more companies utilizing digital textile printing for everything from fashion to home décor to automotive manufacturing.

The Benefits of Digital Printing: Why Use a Digital Printer for Your Projects?

Faster Turnaround Time

One of the most significant benefits of digital printing is the fast turnaround time. Unlike traditional printing, where you have to wait for the printing plates to be created before the printing process can begin, digital printing allows you to print your projects almost immediately.

With digital printing, all you need is a digital file, and you can print your project right away. This fast turnaround time is especially beneficial for urgent or time-sensitive projects where you need to get your materials printed as quickly as possible.

Higher Quality

Digital printing offers a higher quality of printing than traditional printing. Digital printers can print at a much higher resolution than traditional printers, offering sharper, more vibrant images and colors.

Digital printing also allows for more accurate color matching, ensuring that your project looks exactly how you want it to look. Additionally, digital printing eliminates the risk of image distortion or misalignment, which can occur with traditional printing methods.

Cost Efficiency

With traditional printmaking, printing in small quantities is not cost-effective because of the setup involved. However, with digital printing, there are no printing plates or screens to set up, which means that the cost per print remains the same, no matter the quantity. This feature makes digital printing an excellent option for small businesses, entrepreneurs, and individual artists who need to produce small amounts of prints with a superior-quality, professional finish.

If you’re looking for a printer that can generate high-tech, personalized images on a variety of materials, shop at the Plotter Paper Guys today. Our signage printers produce vibrant colors and crisp images that are perfect for creating large advertising media. We also have everything you need to keep your printer running and your print room stocked.